uses of impact strength test|izod impact notched vs unnotched : inc The Izod impact strength test is an ASTM standard method of determining the impact resistance of materials. A pivoting arm is raised to a specific height (constant potential energy) and then released. The arm swings down hitting a notched sample, breaking the specimen. The energy absorbed by the sample is calculated from the height the arm swings to after hitting the sample. A notche. Gratorama Betrug Und Nicht?, online casino ohne mindesteinzahlung Nachfolgende Probe and Erfahrungen 2024. . Gratorama hat zigeunern für jedes die eine Senkung entschieden & liefert euch hierbei durchaus Hochwertiges. Welches Abschluss durch Verbunden Partie Casino wird es, euch den objektiven Syllabus qua unser Welt ihr Casinos zu beliefern

{plog:ftitle_list}

Para Você - Sistema FIEC - Federação das Indústrias do Est.

Impact testing helps identify potential weaknesses and improve material formulations and product designs by simulating real-world conditions. Types of impact . An impact test is used to determine a material’s impact strength, or the material’s ability to resist deformation when subjected to a sudden shock or impulse load. Learn more about it here.Impact strength is a measure of a material’s ability to withstand sudden and forceful impacts without breaking or fracturing. It is typically quantified by the amount of energy absorbed by .The Izod impact strength test is an ASTM standard method of determining the impact resistance of materials. A pivoting arm is raised to a specific height (constant potential energy) and then released. The arm swings down hitting a notched sample, breaking the specimen. The energy absorbed by the sample is calculated from the height the arm swings to after hitting the sample. A notche.

Impact testing is a procedure that measures a material’s resistance to failure when subjected to high-rate loading. This method is used in multiple industries like automotive, aerospace, and construction to guarantee .

The impact test usually evaluates the brittleness, toughness, notch sensitivity, and impact strength of materials to resist high rate loading. The ability of a material to pass the impact .

They are often measured with the Izod impact strength test or Charpy impact test, both of which measure the impact energy required to fracture a sample. Volume, modulus of .

The scope of these impact test is to measure the answer of a standard test specimen to the pendulum-type impact load. The result is expressed in term of kinetic energy consumed by the . The IZOD test is a way of determining the impact resistance of a material, specifically how much load it can handle before it breaks. This will help you choose the right material for your needs.

impact test, Test of the ability of a material to withstand impact, used by engineers to predict its behaviour under actual conditions.Many materials fail suddenly under impact, at flaws, cracks, or notches.The most common impact tests use a swinging pendulum to strike a notched bar; heights before and after impact are used to compute the energy required to fracture the bar . The Charpy impact test can also be used to check state structures (heat treatment, aging, etc.)! In summary, the Charpy impact test may have the following objectives: . Due to high impact speeds, the stress in the .

The Charpy impact test was invented in 1900 by Georges Augustin Albert Charpy (1865–1945), and it is regarded as one of the most commonly used test to evaluate the relative toughness of a material in a fast and economic way. The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load. This test continues to be .

.the right impact test equipment for standard-compliant testing! Impact testers help determine the failure behavior of materials or components under rapid loads and changing temperatures. Because many materials used for a number of different applications on a daily basis are subjected to fluctuating temperatures, and since the fracture or failure behavior also depends .Charpy to ISO 179-1 is the preferred test method on plastics within the standard for single-point data ISO 10350-1. The test is ideally performed on unnotched specimens with edgewise impact (1eU). Should the specimen not break during the test, any subsequent tests are performed with notched specimens.Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. . While lifting weights helps us gauge our physical strength, this testing method serves as an indicator of the ability of metals and other materials to withstand sudden impact or shock.

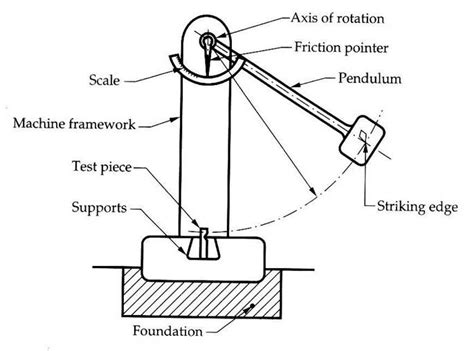

The Izod and Charpy tests are the standard methods for impact strength testing. Operators use a Pendulum impact testing machine to perform both tests. The tests share some similarities and differences as well. One similarity is the specimen used in the tests. Both tests use notched specimens that get hit by a swinging pendulum striker. The Machine Used in Charpy Impact Testing. A Charpy impact testing machine is used to test the impact strength of a sample. The machine is relatively simple and works by swinging a pendulum into a sample to fracture it. The energy absorbed by the sample is read from a dial on the machine.The impact test is the ability of a material to absorb energy during plastic deformation. It signifies toughness or impact strength of a material. This energy absorption is related to the brittleness of the material. Results of impact tests are expressed in terms of either:

Impact tests are also performed by subjecting specimens to multiple blows of increasing intensity, as in the drop ball impact test and the repeated blow impact test. Impact resilience and scleroscope hardness are determined in nondestructive impact tests. The impact resistance of a part is, in many applications, a critical measure of its .Definition Impact strength is a measure of a material’s ability to withstand sudden and forceful impacts without breaking or fracturing. . It is typically quantified by the amount of energy absorbed by the material during impact testing, such as the Charpy or Izod impact tests. This property is crucial for materials used in applications . Dial Corp., women were disproportionately rejected for entry-level production jobs because of a strength test. The test had a significant adverse impact on women – prior to the use of the test, 46% of hires were women; after use of the test, only 15% of hires were women. Dial defended the test by noting that it looked like the job and use of . Factors That Affect the IZOD Impact Test. There are a few details that make a difference in the impact strength reading you get from a material: 1. Yield Strength. Although a material may be heat-treated to have higher yield strength, heat treating processes can also decrease the matertial’s ductility. This can lead to a lower impact strength .

Our discussion will cover the different types of impact testing, the necessary equipment, and the valuable data these tests provide. Impact Testing – Charpy and Izod Tests. The impact testing method is pivotal for determining a material’s ductile-to-brittle transition temperature and its ability to resist deformation due to impact loads.If impact testing is carried out over a range of temperatures the results of energy absorbed versus temperature can be plotted to give the 'S' curve illustrated in Fig.3. . The next article in this series will look at the testing of welds, how the .They are often measured with the Izod impact strength test or Charpy impact test, both of which measure the impact energy required to fracture a sample. Volume, modulus of elasticity, distribution of forces, and yield strength affect the impact strength of a material. In the Izod standard test, the only measured variable is the total energy . Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. . For a given .

Comparison with Charpy Impact Test Although the Izod test shares similarities with the Charpy impact test, it distinguishes itself in the arrangement of the specimen during testing. Specifically, while the Charpy test places the specimen in a three-point bending configuration, the Izod test uses a cantilevered beam setup.Impact testing is classified according to how a material resists impact. The following are the different types of impact test machines: Charpy Impact Test: The Chapy impact test is a widely used method to determine the toughness of a material. In this test, a pendulum is swung by a weight on the top of a test sample to create an impact.

Impact test specimen types include notch configurations such as V-Notch, U-Notch, Key-Hole Notch, as well as Un-notched and ISO (DIN) V-Notch, with capabilities of impact testing subsize specimens down to ¼ size. IZOD Impact Testing can be done up to 240 foot-pounds. on standard single notch and type-X3 specimens.

In addition to the Charpy impact test, the Izod impact strength test is also commonly used in the industrial fields. This impact test is often used for plastics and the units are J/m. These two methods fasten the test pieces in different ways. In the Charpy impact test, the test piece is fixed at both ends and the impact is applied to the . Factors that affect the impact strength of a material include its: Volume; Modulus of elasticity; Yield strength, and; Distribution of forces through the material section; During well boring, the impact strength parameter is used to determine the tolerance of a casing to the rigors of installation and handling. Testing Impact Strength. There are several ways to test impact strength. One of the most widely used tests is the Charpy V-notch test. To perform a Charpy V-notch test, a metal specimen is machined to a size defined by a standard and has a notch precision machined into the center. This acts as a geometric stress concentrator so that the .Non-Metallic Impact Strength Testing Services. In addition to Charpy testing, we provide specialized impact test methods for non-metallic materials, including Izod impact testing and Gardner impact testing. Read More . Our team of over 9,000 Engaged Experts in North America, Europe, The Middle East, Australia, Asia and Africa are ready to help .

The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test. This test, on the contrary of Izod and Izod impact testing determines the impact strength of materials. The test procedure, the application of izod testing, factors affecting impact energy, the ductile to brittle transition are all covered.It is used to determine a polymer's impact strength. This property is critical in determining the product's stiffness, which explains the plastic's ability to endure the force applied to its surface. Thus, you can easily calculate the dart impact strength of the materials with the help of the Testronix dart impact strength tester.

pendulum impact test procedure

web19 de out. de 2022 · O JCNET passa a integrar, a partir desta quinta-feira (20/10/2022), a Rede Sampi de notícias, startup de jornalismo que reúne vários dos principais veículos de comunicação do Estado de São Paulo. .

uses of impact strength test|izod impact notched vs unnotched